Your product’s design determines your maximum consumer appeal, performance, and profitability. Your manufacturing, marketing, and sales efforts seek to achieve the design’s potential. Your product can never be better than it is designed to be.

As the primary stakeholder in your invention’s success, you need to be intimately involved with its design. Even though you may have several industrial designers, engineers, and consultants contribute, you are still the one deciding what the design goals are, which directions to explore, and when we are finished. This post is an inventors guide to managing 3D CAD services.

As a professional design engineer, I don’t expect the typical inventor to do their own CAD design any more than a doctor expects his patients to do their own stitches. It’s not that you couldn’t, it’s just generally a painful route. But, like your doctor, designers need critical input and feedback from you throughout the design process. Here are four tips for entrepreneurs seeking to maximize the creative design process.

-

Write it down

Establishing a vision match with your design team is like picking the corner stone for a building. It all lines up from there, so be specific and don’t rush. In what is often called a requirements document, the inventor needs to describe what customer problem a product solves, and what success metrics will be used. Requirements cover both business and technical topics. Discuss these requirements with your team, and make sure they can re-iterate them with understanding. The format isn’t important, and yes the requirements may change along the way, but what’s most important is that they are discussed, understood, and agreed upon.

-

Be descriptive beyond words

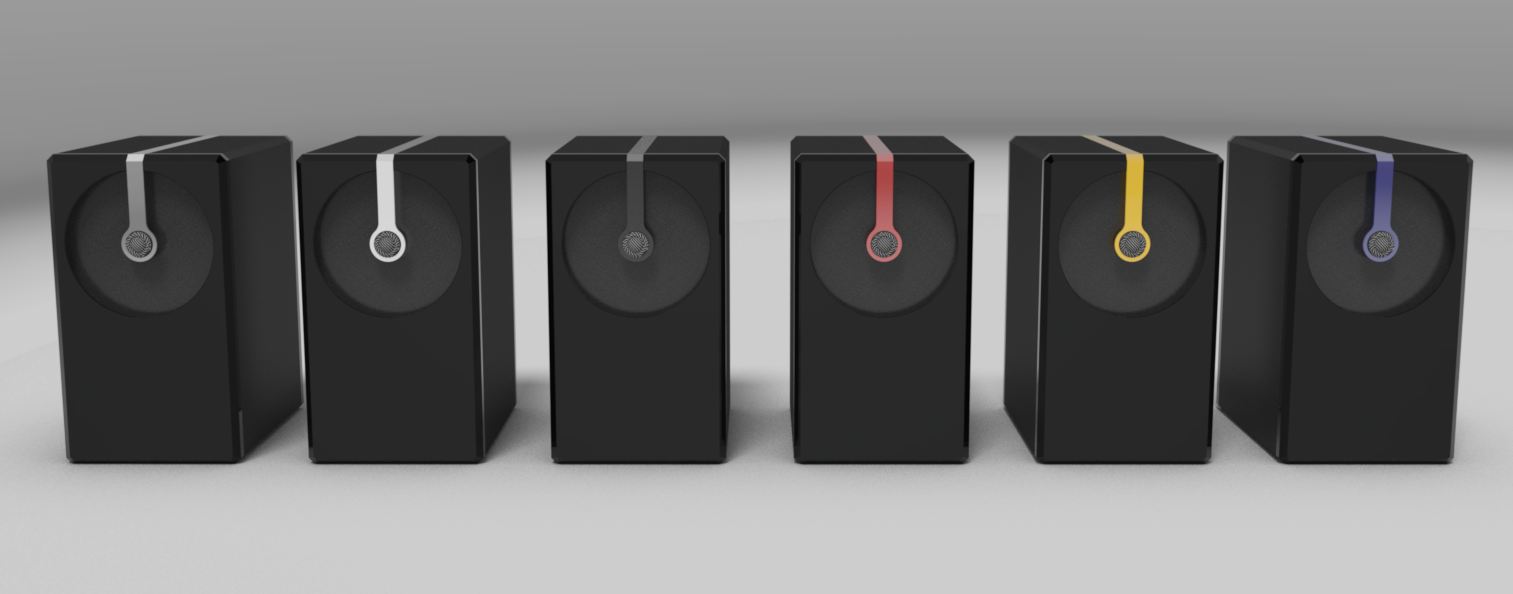

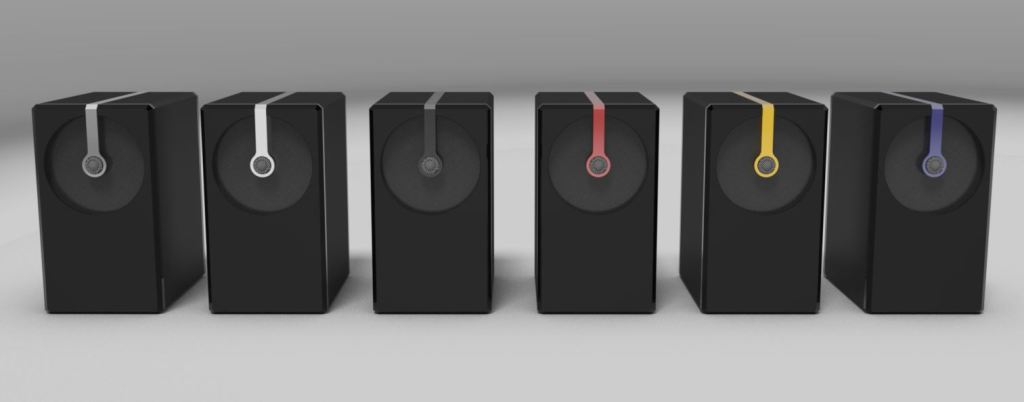

Do you like writing? I hope so, because if a picture takes 1000 words, a fully engineered, manufacturing ready 3D model takes 1000^3. That’s a billion for the non enginerds out there. You and your design team can save a lot of word time by using pictures to communicate. You probably expect your CAD designer to send you screenshots and an Autodesk® Design Review or SolidWorks® eDrawings® file to review as your design progresses. But, have you considered that your feedback can also be visual? I love it when my clients find pictures of colors, materials, and shape online to guide our discussions. I also instruct them to sketch their change requests right on top of the screenshots I send. They can use the 3D Design Review or eDrawigns file to take their own screenshots to point out question areas. I’ve had clients build models out of clay to show me on a video call. All of these techniques cut down discussion time by clearly articulating concepts visually.

-

Design for manufacturing

For many, manufacturing is such a costly part of bringing a product idea to market that they have to raise investment funds. Some individuals take a licensing approach and pass the burden on to another company, along with a majority of the profitability. No matter which route you take, realize your design will determine your manufacturing costs well before you start seeking production volume bids. Routinely ask your design engineers, “How will we manufacture that?” Spend time learning about the materials and fabrication techniques recommended. Keep track of your expected volume and unit cost projections as a design advances. By the time you are done with your design team, you should know enough about the manufacturing process of your product to start contacting suppliers yourself. If you don’t like their manufacturing bids, they will simply tell you to go back and change the design.

-

Predict performance

Product sales are difficult to judge before you have a product to show. Product performance goals are often not measured until a physical prototype exists. Even then it may not perform the way a mass production version will. With modern technology, you don’t really have to wait until a prototype is done to start collecting performance data. You should be showing trusted advisers photorealistic renderings of your product during the design cycle, when their input can be incorporated most cost effectively. Your engineers should be telling you exactly how much your product will weigh well before you hold it. They have technology that can tell you how long your product will last using material A vs material B. Such research and analysis can be costly and time consuming, but consider this truth:

Knowing the answers to performance questions gets easier with time, however improving the answers gets more difficult.